WB-MIR v2 - Modbus IR Remote Control

This page describes the WB-MIR v2 device, which is being released from 11.2017. Previous model description: WB-MIR v1.

Trainable module with IR transceiver for IR control of various devices, including air conditioners, TVs, etc. The module is controlled from the controller or PC via RS-485 bus by Modbus RTU Protocol commands.

Inputs

The module is powered by V+ and GND screw terminals, the RS-485 line is connected to inputs A and B. The DS18B20 external temperature sensor is connected via a parasitic power supply circuit, when the +5V and GND terminals are connected and connected to the GND terminal, the data output is connected to the 1-W(1-Wire) terminal.

Depending on the modification, the device may have an internal temperature sensor (NTC thermistor).

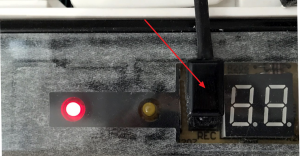

The WB-MIR v2 module requires an external IR transmitter (included). A 3.5 mm Jack is provided for connecting the transmitter.

In the firmware version 4.0.0 and above, it is also possible to configure the 1-W input of the device as a counting one.

Installation

The module is mounted in the immediate vicinity of the device or inside the housing of a controlled device, such as an air conditioner. If further training or retraining of the module is planned after installation, the IR receiver should be located in an accessible place. The IR transmitter, placed on a wire, ~140 cm long, is attached next to the IR receiver of the controlled device to a double-sided tape (included) so as to ensure stable transmission of IR control commands, but to retain the ability to control the device from the remote without blocking the IR receiver of the device completely.

Specifications

| Option | Value |

|---|---|

| Power | |

| Supply voltage | 9 — 24 V DC |

| Power consumption |

0.1 W |

| Transmitter range | < 1m |

| External sensor | Digital temperature sensor DS18B20 can be connected. |

| Terminals and wire section | |

| Recommended wire cross-section with NSUI, mm2 | 0,75 — 1 |

| Length of the standard sleeve NSUI, mm | 8 |

| Torque of screws, N∙m | 0,2 |

| Control | |

| Management interface | RS-485 |

| Interface isolation | Uninsulated |

| Communication protocol | Modbus RTU, address is set by software, factory settings are indicated on the label |

| RS-485 interface parameters |

speed 9600 bps; data bits 8; parity N; stop bits 2; Starting from firmware version 3.1.0 parameters interfaces can be configured programmatically:

|

| Number of stored IR commands | |

| Number of teams |

|

| Command duration | The maximum command length is 508 registers, plus two registers indicates the end of the command.Each register encodes the duration of a high or low signal level (sequentially) in microseconds. |

| dimensions | |

| L x W x h |

|

| operating Conditions | |

| Air temperature | -40°C to +80°C |

| Relative humidity | up to 98%,without moisture condensate |

Learning and using the module

Detailed description and use of the module, and a map of the registers is described in section how to work with the IR receiver in the WB-MS WB-MSW, WB-MIR devices.

Additional functionality

Address change is broadcast (slave_id 0) team record (WRITE_SINGLE_REGISTER) to holding register with address 128 (0x80).

The signature, 6 bytes long, lies at address 200. The signature is unique for each device model and allows you to identify the model. To obtain the signatures, fulfill READ_HOLDING_REGISTERS address 200 length 6. Writing to this area of memory is not supported and error 3 is returned when attempting to write to an invalid location.

Register map

Registers related to IR are described in detail in the section instructions for working with IR transceiver in WB-MS, WB-MSW, WB-MIR devices.

| Register/ address | Type | Read/ write | Default | Format | Purpose | Versions

insertions |

|---|---|---|---|---|---|---|

| 6 | input | R | 0x7FFF | °C × 16 (signed) | Temperature with built-in sensor | |

| 7 | input | R | 0x7FFF | °C × 16 (signed) | Temperature from external 1-Wire sensor | |

| 20 | input | R | 0 | °C × 16 (signed) | Temperature from the first external 1-Wire sensor. In case of an error, the sensor retains the previous valid value (sensor status read from the discrete register 16). | starting with firmware 4.6.0 |

| 104-105 | input | R | 32-bit unsigned int | uptime counter in seconds | ||

| 110 | holding | RW | 96 | baud rate / 100 | RS-485 port speed, "'divided by 100"'. Permissible speeds: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200 (configure RS-485 communication parameters for Wiren Board Modbus devices) |

>3.1.0 |

| 111 | holding | RW | 0 | configure the RS-485 port parity bit. Valid values: 0 - no parity bit (none), 1 - odd (odd), 2 - even (even) | ||

| 112 | holding | RW | 2 | number of stop bits of RS-485 port. Valid values: 1, 2 | ||

| 120 (0x78) | holding | RW | 0 | other than 0 | write to the register causes a reset of the module without saving state | |

| 121 (0x79) | input | R | - | mV | current supply voltage of the module | |

| 128 (0x80) | holding | RW | 1 | The Modbus address of the device | ||

| 129 (0x81) | holding | RW | 0 | 0 or 1 | Switch to bootloader mode | starting with firmware 4.5.0 |

| 200-206 | input | R | see device Signature | signature | ||

| 220-241 | input | R | __date__ _ _ time__ | the build date of the firmware | ||

| 245 | holding | RW | 216 | °C × 100 (signed) | Self-heating compensation of the built-in temperature sensor.

The register value is subtracted from the temperature measured by the built-in sensor (register 6) |

|

| 250-269 | input | R | string, null-terminated | firmware version | ||

| 270-271 | input | R | 32-bit unsigned int | unique identifier (S/N) | ||

| 275 | holding | RW | 0 | 0 or 1 | 1-W input mode: 0 - 1-wire, 1 - discrete input | >=4.0.0 |

| 277 | input | R | 16-bit unsigned int | Counter for 1-W input | ||

| 0 | discrete | R | 0 or 1 | Current state of input 1-W: 0 - open, 1 - GND closed. If 1-wire mode is selected for input, the value is always 0. | ||

| 16 | discrete | R | 0 or 1 | Sensor polling status 1-Wire input no. 1: 0 - sensor not connected, 1 - sensor connected and correctly polled | starting with firmware v.4.6.0 |

Device signature

The 6-byte module signature is stored at address 200. The signature is unique for each model of Wiren Board devices and allows to identify the model by Modbus:

| Module | Signature |

|---|---|

| WB-MIR | WBMIR'0x00' |

To get the signature of a device you need to run command READ_HOLDING_REGISTERS at 200 (length of 6 registers). Writing to this area of memory is not supported, and error 3 is returned when attempting to write to an invalid location. Empty spaces in the signature text are clogged with the value 0x00. Starting from register 220, the firmware build date is recorded, in the format numberx00timex00 as a string (example: 'Jan 27 2017 17:01:13'). The length of the record is 21 registers.

Module management from the web interface

To connect the WB-MIR v2 module, use the WB-MIR v2 template, which provides a complete set of module functions from the web interface, including learning.

Consider the main controls of the module and their purpose.

| The name of the control | Appointment |

|---|---|

| Input Voltage | module supply voltage |

| Learn-to-RAM | Write the IR signal in the operational buffer (see section Operational mode). For learning, the control is transferred to ON position, after learning — OFF. |

| Play from RAM | Play the IR signal from the operating buffer (see Operating mode). |

| Learn to ROMx | IR signal Recording ACC. the cell of the ROM (see section DC mode). For learning, the control is transferred to ON position, after learning — OFF. |

| Play from ROMx | Play IR signal from resp. ROM cells (see Constant mode]). For training, the control is transferred to THE on position, after training — OFF. |

| ROMx -> RAM | Copy data from ACC. ROM cells to the online buffer for editing (see Constant mode). For editing, control is transferred to ON position, after editing — OFF. |

| Internal/External Temperature Sensor | Internal/external digital temperature sensor. If the sensor is missing or defective, its name is highlighted in red. |

| Serial NO | the Serial number of the WB-MIR module may be required when contacting technical support. |

| Reset all ROM | Resets the contents of all memory locations. Be careful, ROM cleaning will be done without asking for confirmation! |

Command-line device management

The Wiren Board controller software includes modbus_client utility to work with devices connected to the RS-485 outputs, via Modbus Protocol, the detailed description of the command is on the page Modbus client. Access to the command line is described in SSH.

Register reading example

Let's check whether it is true that we are connected to the module of the desired type. (Module wb-mqtt-serial needs to be stopped). At address 200, a unique signature of 6 registers is stored. Let's read 6 registers, starting with the address 200, and convert the received answer from hexadecimal digits into a character string:

echo -e `modbus_client --debug -mrtu -pnone -s2 /dev/ttyAPP1 \

-a1 -t0x03 -r200 -c 6 | \

grep Data | sed -e 's/0x00/\\\x/g' -e 's/Data://' -e 's/\s//g'`

As a result of the command, we receive string WBMIR. The WB-MIR module in the example has Modbus address 1.

Device firmware update

Starting with the new firmware versions of the device, the firmware update functionality (firmware) via the Modbus Protocol is supported. This makes it possible to extend the functionality of the devices and eliminate errors in the firmware directly at the installation site. Read more about flashing devices described in the article Download firmware to Wiren Board devices. A list of firmware versions that support the update, as well as devices for which this feature is implemented, can be found in Firmware Changelog.

Images and drawings of the device

По ссылкам ниже вы можете скачать изображения и чертежи устройства WB-MIR2.

Corel Draw 2018: WB-MIR2.cdr.zip

Corel Draw PDF: WB-MIR2.cdr.pdf

Autocad 2013 DXF: WB-MIR2.dxf.zip

Autocad PDF: WB-MIR2.pdf