from $37.93 to $98.28

depending on options

- 562 pieces are already at the warehouse

- 500 more in 2-3 months

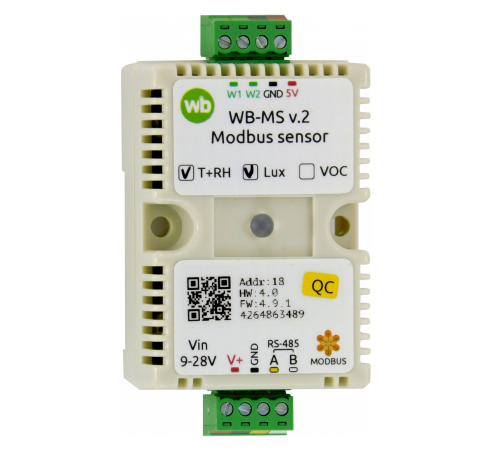

Combined digital sensor for temperature, humidity, light and volatile organic compounds (VOC). It has two inputs that can be used to connect external 1-wire sensors like DS18B20, pulse counting or reading discrete signals.

Applicable to control climate parameters in data centers, server rooms, warehouses, technical rooms, as well as inside automation cabinets and other equipment.

Main characteristics

- 4 measured parameters in one housing.

- Connecting 1-wire sensors.

- Connection of discrete and counting signals.

- The housing can be mounted on a 35 mm DIN rail or through holes on any surface.

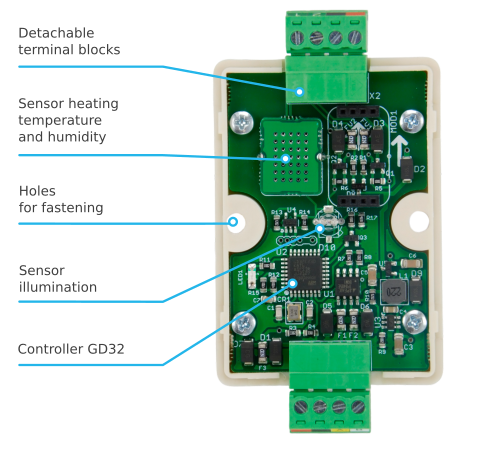

- Heating the temperature and humidity sensor to remove condensation.

- Adjustable temperature compensation.

- Quick and easy integration into the automation and monitoring system.

Measured parameters:

- Temperature: -40°C...+80°C (+-0.5C).

- Humidity: 5...95% (+-3%).

- Illumination: 10...10,000 lux (±20%).

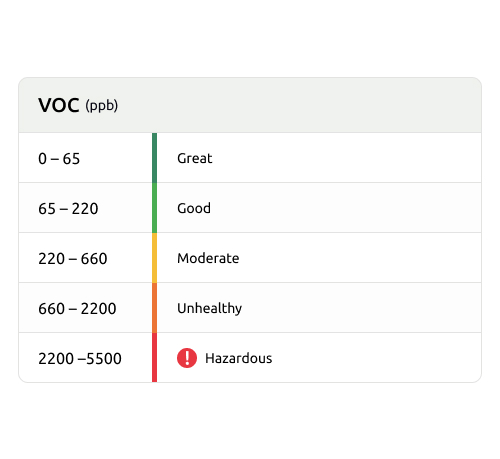

- VOC concentration: 0…60000 ppb.

- Supply voltage: 9…28 VDC.

- Power consumption: 0.1 W.

- Interface: RS-485, Modbus RTU.

- Plastic housing with DIN rail mounting and mounting holes (84x46x29 mm).

Volatile organic substances (VOCs, VOC) are substances released into the atmosphere in the form of gases: evaporation of varnishes/paints and elements of interior decoration (phenol, formaldehyde, toluene, styrene), alcohols, benzene, rotting vegetables, gases emitted by humans, household gas. High concentrations of hazardous VOCs pose a threat to human life and health.

The VOC sensor determines the total concentration of these substances with a typical error of ±15%.

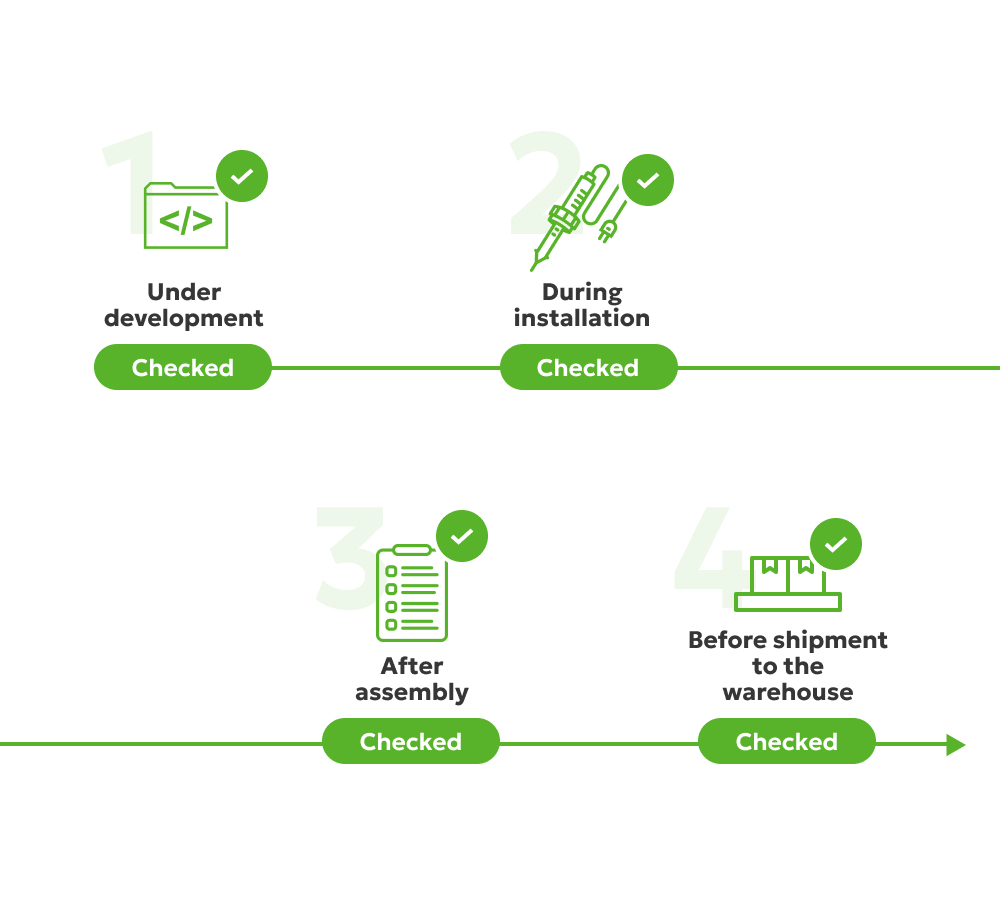

We develop and manufacture all Wiren Board devices ourselves. All devices undergo multi-stage quality control:

- During development — checking the components used for compliance with the declared characteristics and testing the prototype device at extreme operating conditions.

- After installing SMD components — automated optical inspection.

- After soldering the lead components — visual inspection of soldering.

- After assembling the device — functional testing on an automated stand.

- When shipped to the warehouse — control of completeness, stickers, appearance.

Thanks to this approach, the failure rate is no more than 0.5% of all released devices. Read more in the article About device reliability.

If the device fails within two years from the date of purchase, we will replace it for free without the need to send it to a service center.

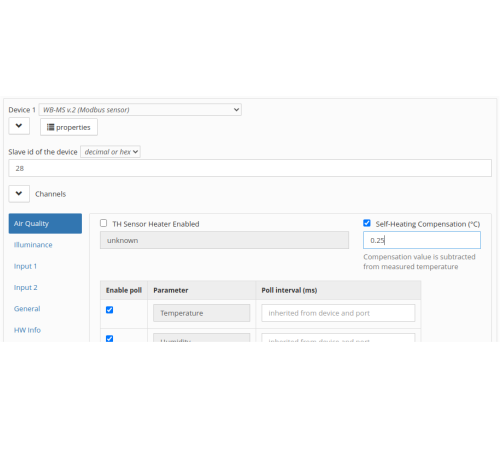

When used with a Wiren Board controller, you can use the mouse in the web interface:

- configure auto-calibration of the VOC sensor and temperature compensation,

- configure polling time,

- enable or disable parameter polling.

When used with other equipment, the dimmer can be configured via the RS-485 bus by writing values to Modbus registers. The register table is open, well documented and available on our website.

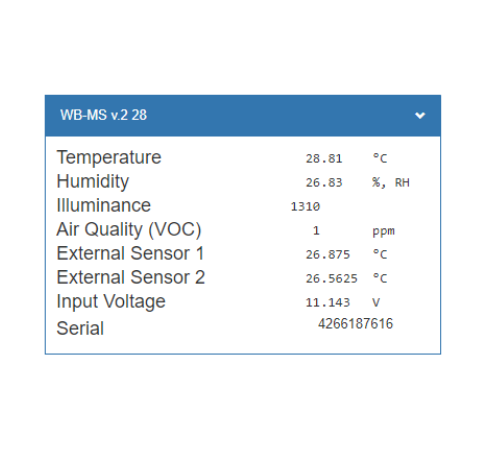

If a Wiren Board controller is used, the measured values are available in the controller's web interface and can be used in automation scripts or transferred to a higher-level system. Only the included channels are displayed in the device card.

The module also transmits all data via Modbus RTU (RS-485), which can be read by any equipment or software that supports this protocol: third-party controllers, HMI panels or SCADA.