from $234.48 to $1 568.10

depending on options

- 613 pieces are already at the warehouse

- 1000 more in 2-3 months

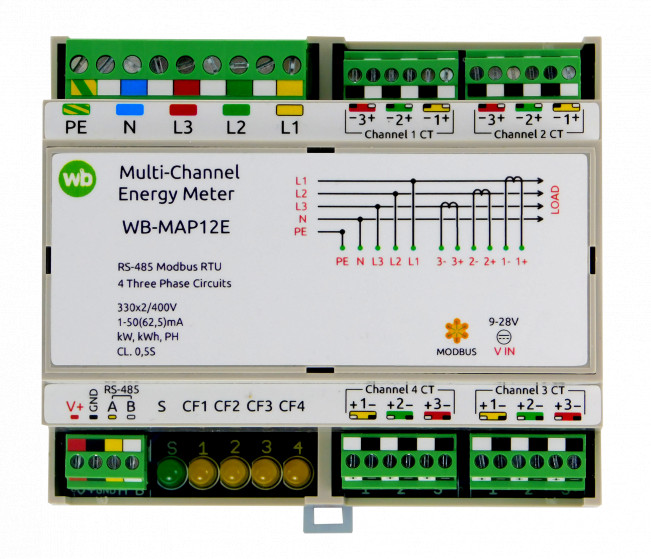

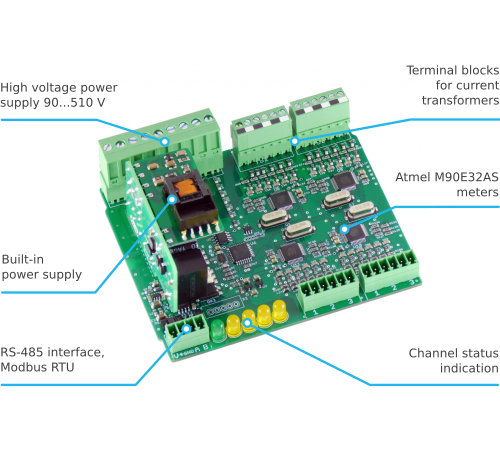

Universal meter for electrical network parameters with 4 three-phase or 12 single-phase measuring channels and RS-485 interface. Used with detachable current transformers.

It is used for measuring all types of electrical parameters in three-phase and single-phase AC networks, for organizing a technical electricity metering system in apartment buildings and office buildings, data centers and smart offices.

Main characteristics

- It is a measuring instrument, suitable for technical accounting.

- Low cost of the measuring channel.

- Stores accumulated readings when power is turned off.

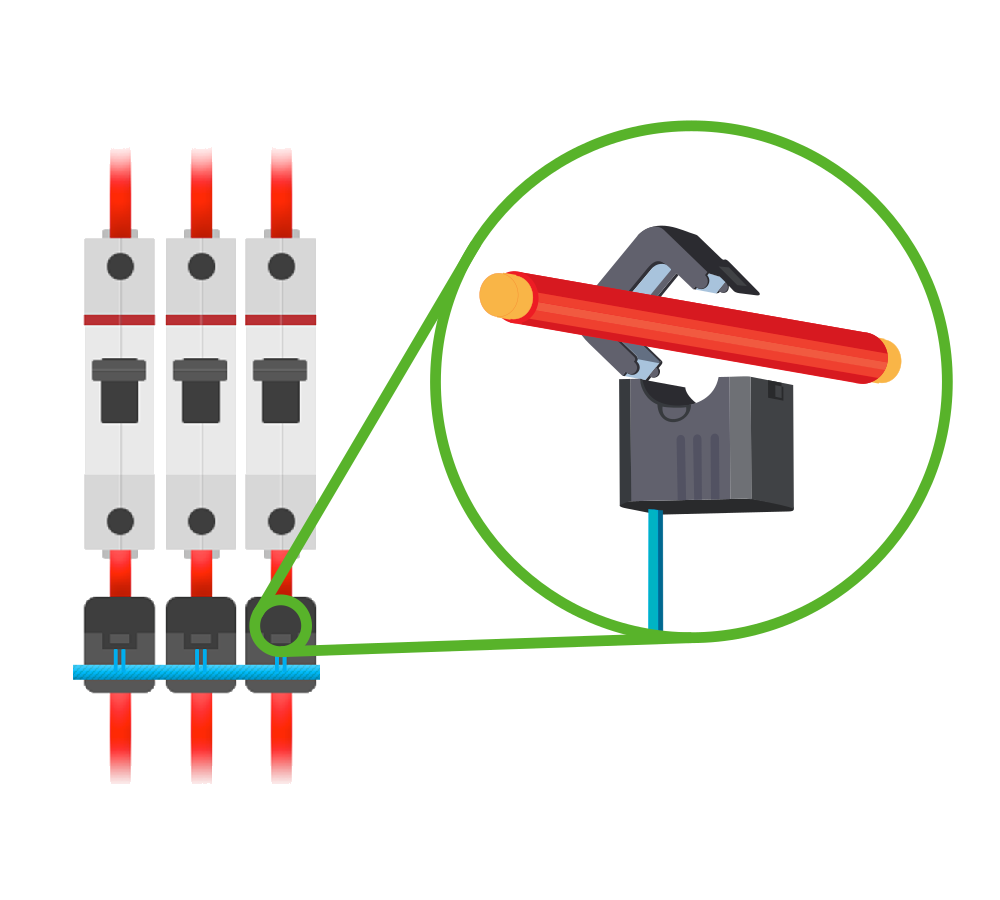

- The use of external detachable current transformers allows installation of the system without disconnecting consumers.

- A large number of measured parameters.

- Customizable phase mapping simplifies installation and commissioning.

- Service life 16 years.

- Fast and easy integration into automation and monitoring systems.

Supports Fast Modbus ⚡, which allows you to instantly deliver the effective voltage value to the Wiren Board controller.

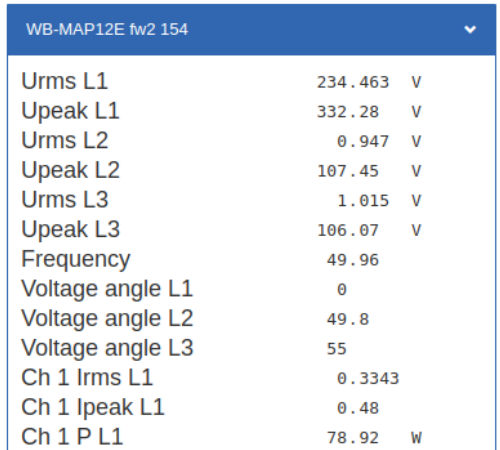

Measured parameters:

- RMS values of current and voltage (Urms).

- Power (active, reactive, apparent, apparent) and power factor.

- Direct and reverse energy (active, reactive, apparent, inactive).

- Total values of power and energy when connecting three-phase loads.

- Amplitude of voltage and current surges. The width of the measured peaks is from 300 μs, determined by filters at the inputs, the peak values are updated periodically, the period is adjustable (minute by default).

- Phase shift angles, frequency.

Specifications:

- To accuracy class 0.5S for active power and energy and 1 for reactive power and energy.

- Supply voltage: 9…28 V direct current and 230 V AC.

- Interface: RS-485, Modbus RTU.

- Extended operating temperature range: -40…+80 °C.

- DIN rail housing, 6 modules.

The meter can be connected to the existing power supply system without interfering with the electrical wiring and the need to disconnect power wires from circuit breakers. For this purpose, current transformers with a split core are used together with the meter. Everything you need to do during installation — connect the phase lines to the meter terminals and put current transformers on the power wires.

The meter is installed on a DIN rail in a distribution board or inside an electrical equipment housing.

WB-MAP12E is used in systems power grid monitoring and at industrial enterprises, office buildings, data centers. Measures all the main parameters of the electrical network, replacing several measuring instruments: voltmeter, ammeter, wattmeter, frequency meter.

The measured parameters can be used to monitor power consumption and quality. As well as identifying emergency situations:

- lack of phases,

- phase voltage unevenness,

- phase angle imbalance,

- voltage fluctuations.

To transmit actual voltage values (Urms), WB-MAP12E uses Fast Modbus ⚡.This allows you to instantly detect phase voltage deviations from the norm and take timely measures to protect electrical equipment.

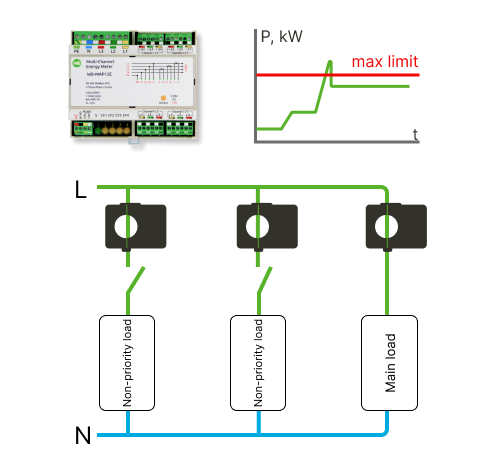

Measured parameters convenient to use in tasks of managing load priorities to control consumption on each line. WB-MAP12E can continuously measure current on 4 three-phase or 12 single-phase channels and transmit readings to the controller. If the permissible current consumption is exceeded, the low priority load is switched off. To disconnect loads you can use Wiren Board relay modules.

If you do not need to measure voltage and energy, then to measure current the meter does not have to be connected to power lines, It is enough to put a current transformer with a split core on the measured line. This makes installation and integration into the automation system easier.

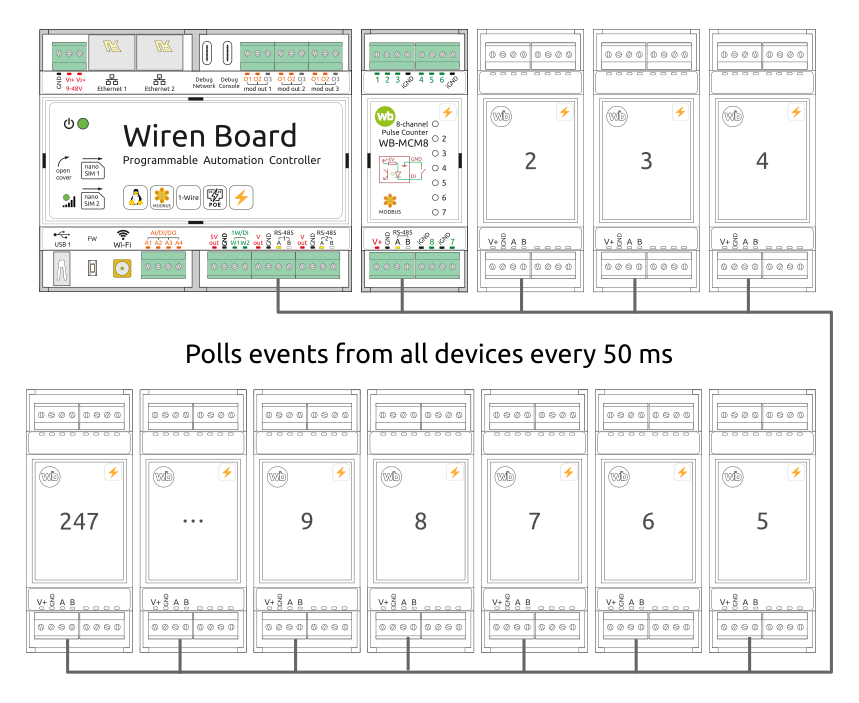

All Wiren Board devices, in addition to the standard Modbus RTU, can work with its extension Fast Modbus ⚡, which adds new features:

- instant polling of input states and measured values via events;

- quick search for devices connected to the controller;

- resolving address collisions on the bus.

Additional features are enabled automatically - if the device supports extension, the controller driver will work with the device quickly Modbus if the device does not know anything about the extension - it will work using standard Modbus RTU.

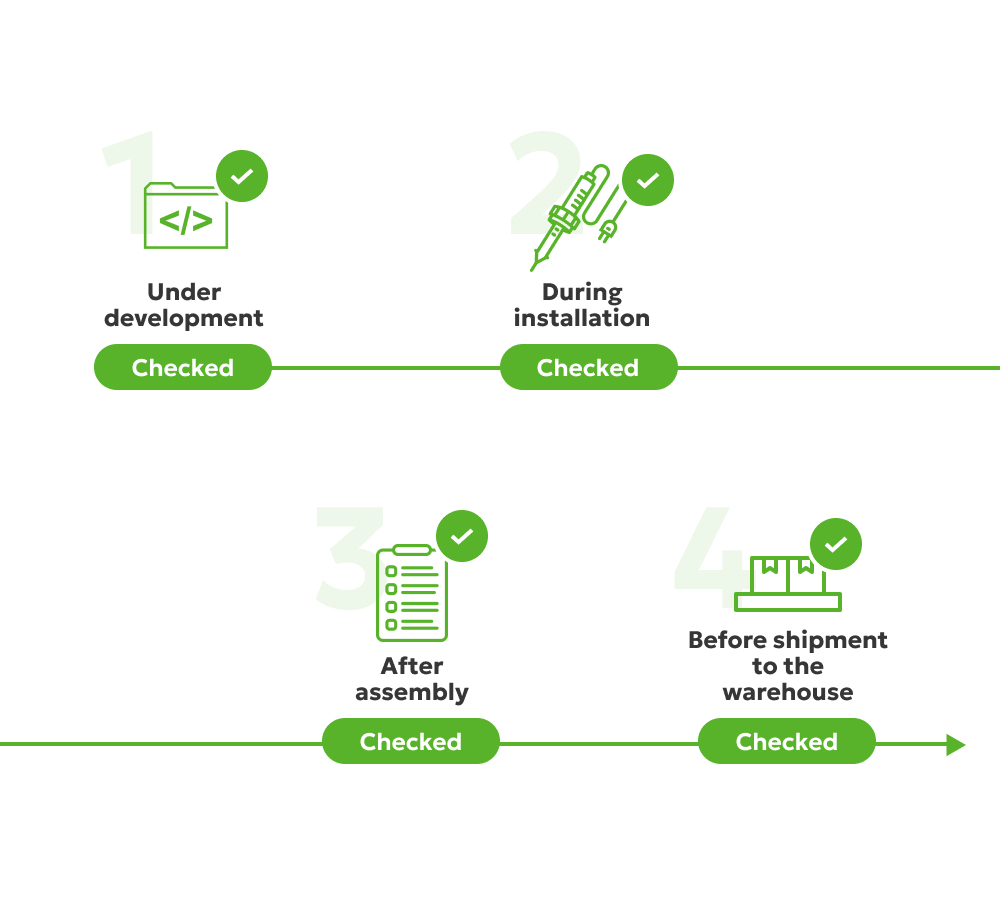

We develop and manufacture all Wiren Board devices ourselves. All devices undergo multi-stage quality control:

- During development — checking the components used for compliance with the declared characteristics and testing the prototype device at extreme operating conditions.

- After installing SMD components — automated optical inspection.

- After soldering the lead components — visual inspection of soldering.

- After assembling the device — functional testing on an automated stand.

- When shipped to the warehouse — control of completeness, stickers, appearance.

Thanks to this approach, the failure rate is no more than 0.5% of all released devices. Read more in the article About device reliability.

If the device fails within two years from the date of purchase, we will replace it for free without the need to send it to a service center.

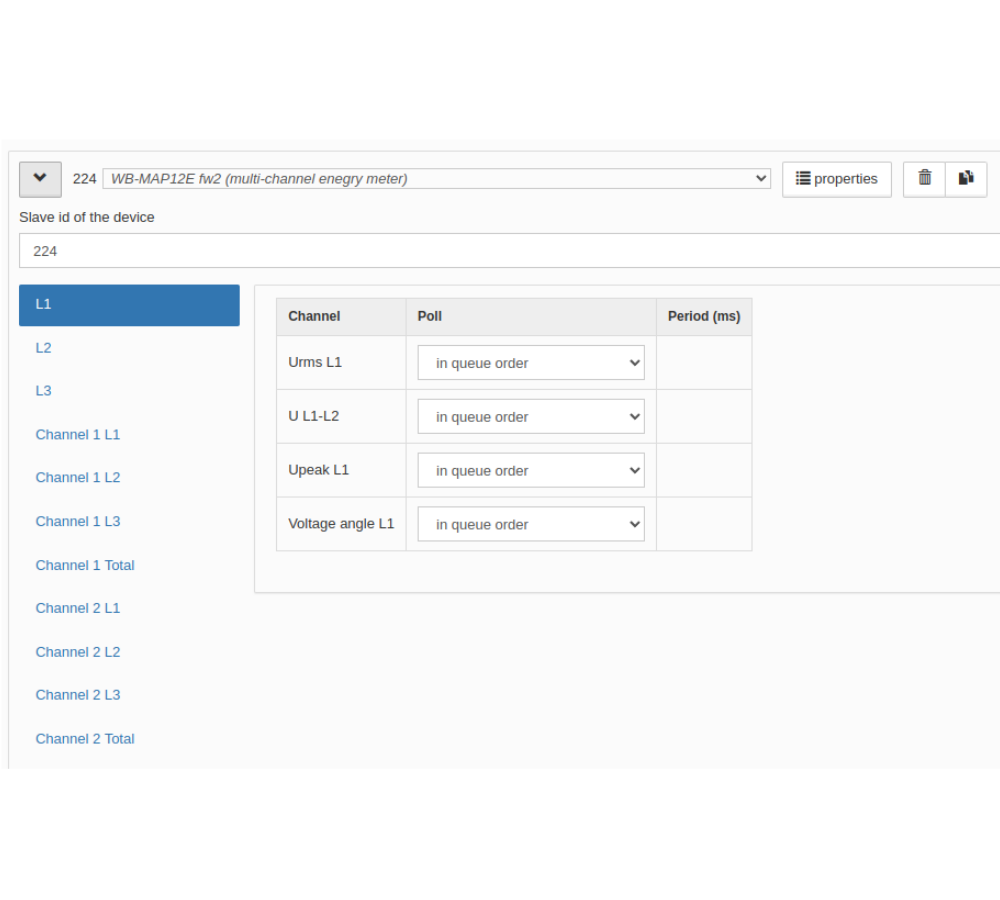

When used with a Wiren Board controller, you can use the mouse in the web interface:

- enter calibration parameters of current transformers,

- configure phase mapping,

- configure the period for resetting peak values,

- enable or disable parameter polling,

- set the data exchange speed.

When used with other equipment, the module can be configured via the RS-485 bus by writing values to Modbus registers. The register table is open, well documented and available online in the device documentation.

The meter does not have its own screen, so the measured parameters are read via the RS-485, Modbus RTU interface.

If a Wiren Board controller is used, the measured values are available in the controller's web interface and can be transferred to the higher-level system. The device card displays only the channels enabled in the survey settings.

All data can be read by any equipment or software that supports the RS-485, Modbus RTU protocol: third-party controllers, HMI panels or SCADA.